Loading... Please wait...

Loading... Please wait...

Common Types of Belts & What You Should know

- Home

- Information

- Common Types of Belts & What You Should know

Flat/Stretch Belts:

In the vacuum industry, flat belts, also known as stretch belts, are very commonly used to drive the brushroll. These are the most common types of belts and must be stretched to be installed. That added tension is what gives your brushroll it's turning power, and prevents the belt from slipping around your brushroll while vacuuming your floors. If you smell burning rubber while sweeping, this is most likely because your belt has begun to slip. Over time these belts lose elasticity, even when the vacuum is not in use. We recommend changing these belts every 6 to 12 months depending on usage. When you purchase new flat belts, they will most likely be shorter in circumference/length than your old belt you are replacing. This is normal, and is because your old belt has begun to lose it's elasticity. Do not be alarmed when you try installing a new belt and it seems too small. If you are struggling to install your new belt, visit your local vacuum dealer/repairman or seek instructional videos on the internet.

- Called Flat or Stretch Belts

- Are Stretched When Installed

- New Flat Belts are Often Shorter in Circumference/Length Than Your Old Belt

- Change Every 6 to 12 Months

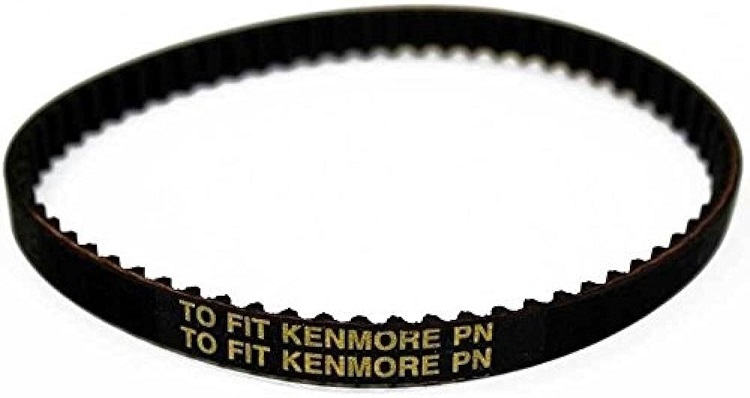

Geared/Cogged Belts:

Some Vacuums require a cogged belt, sometimes called a geared belt. These types of belts have small "teeth" on them that provide a secure mechanism for driving your brush. These belts generally don't need replaced very often, but you can check if yours is due by examining the teeth on your belt. If the belt has begun to fray, the belt has worn very thin, or any of the teeth are missing, then we recommend changing your belt.

- Called Geared or Cogged Belts

- Are NOT Stretched When Installed

- New Cogged Belts are Generally the Same Size as Your Old Belt

- Change as the Belts Begin Showing Signs of Wear

Serpentine Belts:

Serpentine belts have grooves in them, and are even called grooved belts by some in the industry. These grooves run the length of the belt and provide the motor pulley and brushroll more surface area to grip the belt, allowing for a smoother and more secure rotation than a stretch belt. These belts can start to slip, but it is rare as they take years to stretch out, if at all, and are much harder to break than a stretch belt. These belts are very durable and generally only need replaced if they are broken.

- Called Serpentine or Grooved Belts

- Are NOT Stretched When Installed

- New Serpentine Belts are Generally the Same Size as Your Old Belt

- Change These Belts if They Break or Start to Slip